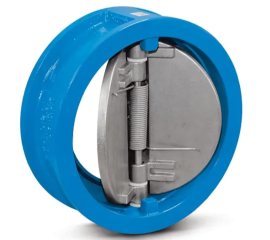

Check valves, or non-return valves, permit fluid flow in one direction, preventing backflow that could damage systems. They're vital in applications like pump discharges, compressor inlets, and chemical plants. By maintaining unidirectional flow, check valves protect equipment and ensure efficient operation across various industries.

Diaphragm valves, featuring a flexible diaphragm that seals against a seat, provide precise flow control and tight shutoff. Their design ensures minimal fluid contamination, making them ideal for industries like pharmaceuticals, food processing, and water treatment. Available in various materials and configurations, diaphragm valves are suitable for handling corrosive or abrasive media.

Dual plate check valves, also known as double-door check valves, feature two spring-loaded plates that open with forward flow and close upon reverse flow, preventing backflow. Their compact, lightweight design reduces pressure drop and minimizes water hammer effects, making them ideal for applications in water treatment, pumping stations, and various industrial systems.

Forged globe valves are designed for precise flow regulation and positive shutoff in high-pressure applications. Their robust forged steel construction ensures durability and reliability, making them ideal for industries such as oil and gas, petrochemical, and power generation. Available in various sizes and pressure classes, these valves offer superior performance in demanding environments.

Forged steel is produced by shaping metal under high pressure, resulting in a refined grain structure that enhances its strength, toughness, and durability. This process yields superior mechanical properties compared to other manufacturing methods, making forged steel ideal for critical applications in industries such as automotive, aerospace, and oil and gas.

Gate valves are designed to either fully open or fully close the flow of fluid in a pipeline by raising or lowering a gate-like disc. They are not suitable for flow regulation, as partial opening can cause damage due to vibration. Commonly used in various industries, gate valves are ideal for applications requiring minimal pressure loss and bidirectional flow.

A pneumatic angle seat valve is an automated valve used for controlling fluids, gases, and steam in pipelines. It features a piston actuator that lifts a seated plug at an angle, ensuring high flow rates and durability. Common in industrial applications, it provides fast response, reliability, and excellent sealing performance.

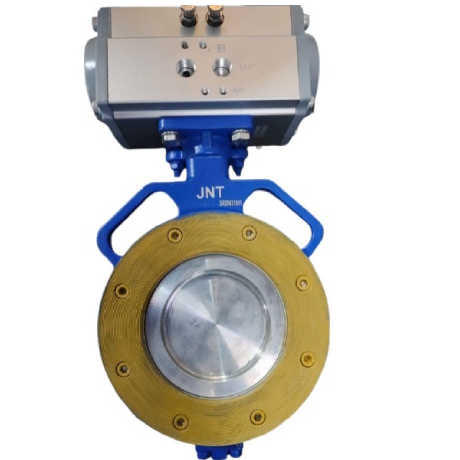

A butterfly valve is a flow control device used in pipelines to regulate fluid movement. It features a rotating disc that pivots around a central axis to open, close, or throttle flow. Common in water, gas, and chemical industries, butterfly valves are lightweight, cost-effective, and offer quick operation.

Knife gate valves are designed to handle challenging media like slurry, viscous fluids, and dry bulk materials. Featuring a sharp-edged gate, they effectively cut through these substances to provide reliable isolation. Commonly used in industries such as mining, pulp and paper, and wastewater treatment, knife gate valves offer efficient performance in demanding applications.

.png)

Non-return valves (NRVs), also known as check valves, are essential components in fluid systems, allowing flow in one direction while preventing backflow. They maintain system pressure, enhance efficiency, and protect equipment from potential damage caused by reverse flow. Commonly used in water treatment, industrial processes, and domestic plumbing, NRVs ensure safe and reliable operation.

Safety valves are crucial components in industrial systems, designed to release excess pressure and prevent equipment failure or hazardous situations. Used in pipelines, boilers, and pressure vessels, they ensure operational safety and system integrity. Made from durable materials like stainless steel and cast iron, safety valves provide reliable pressure control, protecting both machinery and personnel from potential risks.

A solenoid valve brass is an electromechanically operated valve used to control the flow of liquids or gases. Made from durable brass, it offers excellent corrosion resistance and reliability. Commonly used in water, air, and fuel systems, solenoid valves ensure efficient automation in industrial, commercial, and residential applications, providing precise flow control with quick response times.

Shut-off valves are designed to control, regulate, or completely stop the flow of liquids or gases in pipelines. Made from high-quality materials like brass, stainless steel, and cast iron, they ensure durability and leak-proof performance. Commonly used in plumbing, HVAC, and industrial applications, shut-off valves provide reliable flow control for safety and efficiency in various systems.

WCB Globe Valves Flange are durable, high-performance valves made from WCB (Wrought Carbon Steel), ideal for regulating fluid flow in pipelines. Designed with a flanged connection, they ensure secure installation and leak-proof performance. These valves provide precise throttling control, making them suitable for industries like oil, gas, water treatment, and power plants, ensuring reliability under high-pressure conditions.

SS 304 Ball Valves and Needle Valves are essential components used for precise control and shut-off in fluid handling systems. Made from high-grade stainless steel 304, these valves offer excellent corrosion resistance, durability, and performance in various industrial applications. The Ball Valve provides quick on/off operation with a quarter-turn mechanism, while the Needle Valve allows fine flow control with high accuracy.